Polystyrene is made from the monomer styrene, which is a liquid petrochemical.

Types

The three most important grades of styrene are:

- GPPS: General-purpose polystyrene, also known as crystal-clear polystyrene, is a fully transparent, rigid and rather brittle low cost thermoplastic made from styrene monomer. GPPS is a solid product manufactured in the form of 2-5 mm pellets.

- HIPS: High impact polystyrene contains usually 5 to 10% rubber (butadiene) and is used for parts, which require high(er) impact resistance. HIPS is a graft copolymer having polystyrene sidearm. The grafting occurs when some of the radicals react with the double bonds of the polybutadiene.

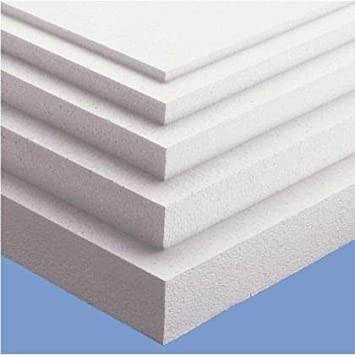

- EPS: Expandable polystyrene consists of micro-pellets or beads containing a blowing agent (usually pentane). The expanded or foamed polystyrene is thermally insulating and has high impact resistance.

Applications:

Uses include protective packaging (such as packing peanuts and CD and DVD cases), containers, lids, bottles, trays, tumblers, disposable cutlery and in the making of models.